Micronaire is a technical term for cotton fibers and indicates fiber fineness and maturity. According to the clarification of the COTTON INC community, micronaire is the measurement of air penetration in condensed cotton fibers. The measurement of micronaire affects the final products' efficiency, performance, quality, and appearance. Micronaire affects extremely different factors such as:

- Cotton waste percentage

- Fiber nep

- Spinning efficiency

- Textile appearance quality

- Dye absorption of final products

Variable Micronair was impressed by humidity, temperature, sunlight, inappropriate air condition, and available nutrition in the cotton growth period. The measurement of fiber micronair should be in an optimum range. The cotton is a natural fiber so the different condition parameters impact on final textile quality. In a short-term cotton growth period, earlier freezing, cotton with less micronair is produced. The thickness of the cell walls of cotton fiber growing in seasonal water flow conditions causes to increase in the measurement of micronair.

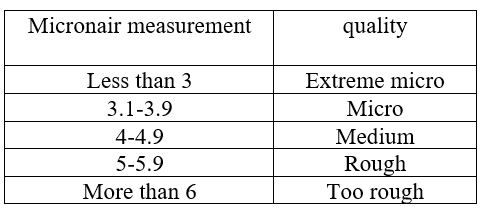

Micronaire is categorized into 5 parts:

Fibers with a micronaire range of 3.7 to 4.2 are suitable for spinning. Prime Seed is vital to get an appropriate micronaire in products; then, considering the air condition of each area various studies have been done to produce the finest seeds for farmers. These fibers included in the range are more expensive than other cotton fibers just because of their proper spinning, easier separating process of cotton waste, increased productive efficiency, and less fiber neps. Less micronaire in cotton fiber (less than 3) produces more waste cotton and many fibers are destroyed. Low micronair or microfibers lead to slow cotton processes such as combing, and cotton cleaning to protect fibers from damage, this decreased speed affect negatively productive efficiency.

With increasing fiber diameters, more resistance against bending is demonstrated, and increased space among fibers results in expanding liquid and air absorption capacity in fibers. Consequently, they are used for hygiene products such as diapers.

Cotton with higher micronaire is used for nonwoven textiles. With decreasing micronaire, cotton fibers become softer while increased micronaire brings rough fibers. Considering textile application, suitable fibers are applied. Where high absorption is necessary, high micronaire in cotton is used; on the other hand, for comfortable products low micronaire in cotton is determined as an appropriate option.

Fibers with higher than 5 micronaires aren’t suitable to spin because of roughness and low flexibility affecting the quality of yarns, also, the spinning process of yarns are struggle. Increased fiber spinning leads to more dyeability and resistance.