Common lengths for mixing with wool: 76, 88, 102 mm (average 88 mm)

Common lengths for mixing with other man-made fibers: 51 mm (longer length increases the tendency to nap)

Common length for air jet spinning system: 38mm,

Common length for open-end spinning system: 32 mm.

(Tensile Properties):

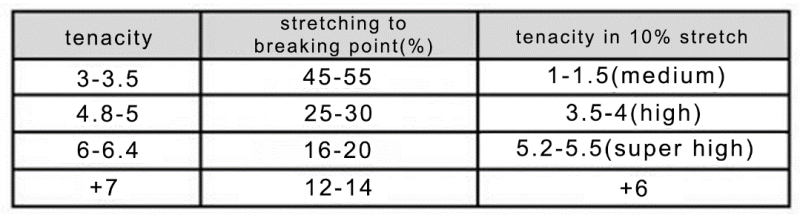

Tenacity (the ratio of tensile force applied to the breaking point per denier)

- Medium: 4.8-5 g/denier

- High tenacity: 6-6.4g/denier

- Very high tenacity: above 7g/denier

Medium and high tenacity is usually used in the production of textile.

Weavers usually prefers high tenacity over medium tenacity because it is easier to weave, but these fibers have 20 -25% less color fastness than medium and have less moist absorption.

Fibers with very high tenacity are usually used to produce 100% polyester yarn and other industrial yarns. Elongation has the opposite relationship with tenacity. Tenacity is important at 10% stretch for fiber blends.

(Crimp Properties):

Crimp (curl and wave) cause tangles of fibers and should be something around10-11 crimp/inch.

Of course, spin finish also creates a similar property of curling, but curling is much more effective than spin finishing.

(Polyester Luster):

- (Bright): 0.05-0.1% TiO2

- (Semi dull): 0.2-0.3% TiO2

- (Dull): 0.5% TiO2

The semi-dull is the most widely used among the mentioned cases.

(Moisture regains):

Polyester is in the category of fibers with low moisture absorption, around 0.8-0.2%.

(Specific gravity) or (Relative density):

The specific density of polyester is something about 1.22-1.38 grams depending on the type of polyester. Polyester has a higher density than polyamide and less than rayon, and the fabrics prepared using them are light fabrics.

(Thermal properties):

The glass transition temperature of polyester is around 75°C, its crystallization temperature is around 130°C, and the melting temperature of polyester is around250-300°C. in general, the important parameters in the fibers used in spinning units are as followers:

- Fineness (grade): at least 1.4denier (equivalent to 1.33ditex). variations in fineness or grade during production, expressed as CV%, should not be more than 6%.

- Tenacity: for this score, 1.4 denier (1.33 ditex) must be at least 6 den/cn with CV%=4

- Elongation (percentage): for this grade of 1.4 denier (1.33 ditex) it should be between 25 and 30%.

- Cut length: in millimeters for this score, 1.4 denier (1.33 detex) (according to the cotton system, it should not be more than 38 and less than 36mm with CV%=6.

- Crimp number: for this score, 1.4 denier (1.33 detex) should not be less than 38. Of cours the customer's order has preference in this case. One of the most important points in the U.P.O around 0.125 to 0.2 is desirable because the use of lubricant, antistatic permanent, and emulsifier play an important role in marking a spin finish oil, and the equipment and facilities for making this spin finish are important. Different unite spin finish units are very important in the section of the spinning melting tension line to reach UPO=0.125.

- The percentage of moisture absorbed in polyester fibers: (%Wet) for this grade of 1.4 denier (1.33 ditex) should be a number between 0.5 + 1 percent.

- (shrinkage): also for this grade 1.4 denier (1.33 detex) should be a number between 0.05 +2.5.