What is the scouring process?

Natural fibers typically contain dust, oil, wax, minerals, and other impurities that must be removed before further processing. Scouring is the preferred method for removing these impurities. The primary wet process utilized in the textile industry before dyeing or printing is scouring. The principal objective of scouring is to eliminate both natural and synthetic impurities, rendering it cleaner and more absorbent.

Scouring purposes

- Natural and synthetic oils, fats, and waxes are removed.

- Hydrophilicity is improved.

- Absorption is enhanced.

- Prepared for the next process.

- Obtaining a uniform result in bleaching.

The scouring process depends on the following:

- 1-The type of used cotton

- Cotton color

- 3-Cleanliness of the cotton

- 4-Finense of the cotton

- Fabric structure

Chemicals and their purposes in the scouring:

Caustic soda: NaOH neutralizes acidic substances, and saponifies glycerides (waxes and oils), and dissolves silicates.

Sodium Silicate: This penetrating substance breaks down lignin into particles. It is typically added to fabrics with numerous impurities and different materials.

Wetting agent: reduces and minimizes surface tension.

Detergents: They help emulsify fats, oils, and waxes to remove stains caused by oil, suspending the material after removal.

Sequestering agents: They deactivate metal ions.

Salt: makes detergents more effective.

Solvent: helps to emulsify by dissolving oily substances.

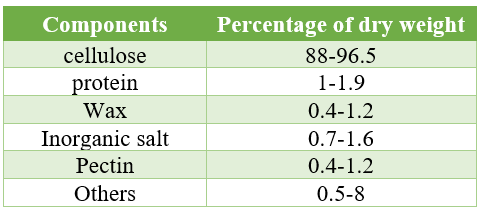

Impurities in the cotton

The impurities of cotton fibers vary from 4 to 12 percent.

Cotton scouring chart:

Cotton (Fabric/ fiber)

↓

Check

↓

It is moistened by NaOH solution

↓

Emulsification

↓

detergents

↓

Scouring

↓

Scoured fabric