Cotton fabric is one of the most used types of fabric in the world. Cotton fabric is obtained from the fibers around the seeds of the cotton plant, which appear round and fluffy after the seeds mature. The production steps of these fibers can be summarized as follows:

- Defoliation:

At this stage, leaves and thorns are separated from the cotton plant.

- Machine Harvesting:

At this stage, harvesting is done by machine, and its big impurities are separated from the fibers.

- Separating:

At this stage, the cotton cleaning machine separates the cotton seed from the boll and removes its dirt and garbage.

- Transferring:

At this stage, the cotton is transferred to the spinning factory.

- Carding:

In the carding stage, cotton fibers are converted into long threads (wicks).

- Spinning:

The threads (wick) produced in the previous step are spun and turned into yarn.

- Finishing and dyeing:

Then cotton threads can be finish or dyed.

- Weaving:

At the end, the produced threads are used for fabric weaving.

To produce cotton fabric, as mentioned, the cotton seed must first be separated from the boll. In ancient times, this step was done by hand, but in 1794, Eli Whitney, an American entrepreneur, invented the cotton gin, a mechanical device that greatly speeds up the process of separating cotton. Today, there are automatic cotton ginning machines that have made this process easier for the workers. These machines can harvest cotton bolls from agricultural fields and other machines can separate the seeds from the bolls.

The main uses of cotton fibers:

- Use in clothes such as t-shirts, jeans, etc

- Use in the production of towels

- Use in the production of mattresses and sleep products

- Use in the medical industry

statistics show that approximately 75% of the world's clothing products contain at least some cotton. Because cotton has high breathability and absorption, it is usually used to produce warm clothes. On the other hand, its softness and proper hanging make it a suitable option for formal and business clothes.

The most important cotton producing areas:

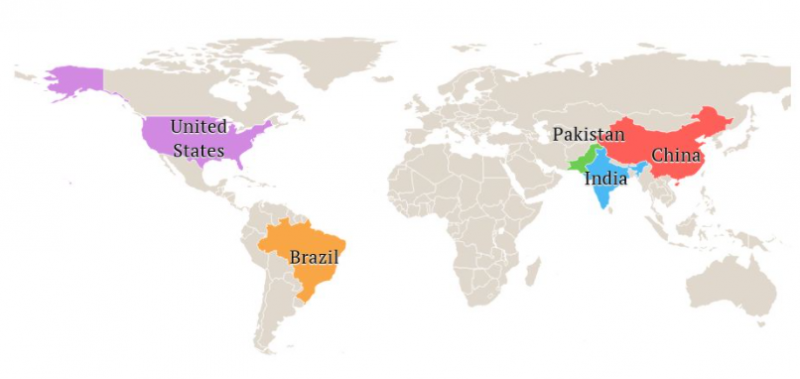

India and China are often known as biggest cotton producers in the world.

According to reports, India produced 6,205,000 tons of cotton between 2017 and 2018, surpassing its East Asian rival, which produced 5,987,000 tons of cotton fiber during the same period.

US is one of the other biggest cotton producers in the world by making 4555000tons.

While these three countries produce the most cotton in the world, other countries such as Brazil, Pakistan and Australia also consistently produce more than 1 million tons of this fiber per year.

Types of cotton fibers:

- Short cotton fiber(SS)

It is cotton that consists of short fibers and has common uses, but it is not as soft as other types.

- Long cotton fiber(LS)

This type of cotton has better properties due to its longer length and its therefore more expensive.

- Very long cotton fiber(ELS)

This cotton is the longest and most luxury types of cotton available.

- Egyptian cotton

Egyptian cotton is a term that refers to certain forms of LS or ELS cotton. For example, Giza 45 cotton is over 45 mm (1.77 inches) long, making it one of the longest and most luxurious types of cotton available.

- Pima cotton

Pima cotton is a type of ELS cotton developed through a partnership between the United States government and the Pima Indians in the early 20th century and is considered one of the most durable types of cotton.

- Supima cotton

Supima cotton is a type of Pima cotton that American Supima Association (ASA) are interested in. Supima cotton can only be grown organically in the United States.