Acrylic fiber is a widely used commodity to produce fiber filaments and fabric. Acrylic fiber (or polyacrylonitrile fiber) is usually defined as a polymeric material which contains at least 85 percent by weight of acrylonitrile monomer. The main comonomers employed are neutral esters, such as methyl acrylate and vinyl acetate. The comonomers improve solubility of the polymer in solvent, improve fiber flexibility and morphology. Often, a small percent of an ionogenic comonomers such as sodium itaconate is also incorporated to increase the number of dye receptor sites in the polymer.

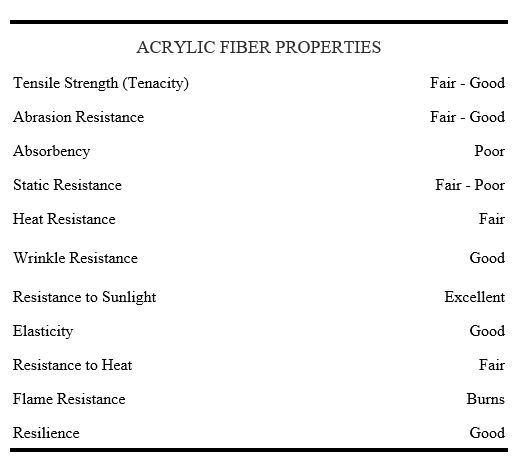

Acrylic fibers compete in the market place with other synthetic fibers (such as polyester and nylon) and natural fibers (such as cotton and wool). Acrylic fiber properties are compared to other natural and synthetic commodity fibers in the PERP report.

PROCESS ECONOMICS

Nexant has estimated costs of production for world scale, state-of-the-art, acrylic fiber plants operating via the two commercial process technologies:

- Solution polymerization with wet spinning (West Europe and China location bases)

- Suspension polymerization with wet spinning (West Europe and China location bases)

Sensitivity of the production cost to fluctuation in acrylonitrile prices and plant scale has been analyzed.

All cost tables given in this report include a breakdown of the cost of production in terms of raw materials, utilities direct and allocated fixed costs, by unit consumption and per metric ton and annually, as well as contribution of depreciation to arrive at a cost estimate (a simple nominal return on capital is also included).

On a qualitative basis, the advantages and disadvantages of the polymerization processes suspension, solution, emulsion, bulk) and spinning processes (wet, dry, air gap, melt) for producing acrylic fiber are compared.

COMMERCIAL MARKET REVIEW

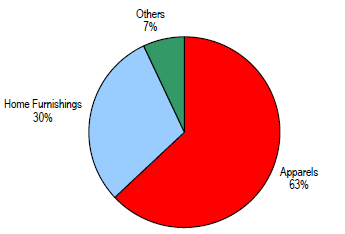

As shown in the figure below, major apparel and home furnishings applications for acrylic fiber account for 63 percent and 30 percent, respectively, of the global acrylic fibers market. These applications reflect its properties primarily as synthetic wool and, to a lesser extent, synthetic cotton. Thus, in garments it is found in sweaters, socks, fleece wear, circular knit apparel, sportswear and children’s wear. In home furnishings, it is used in blankets, area rugs, upholstery, awnings, and outdoor furniture.

Partially carbonized and pre-oxidized acrylic fiber tow is used as an asbestos replacement in applications such as clutch and brake pads. Fully carbonized sub-tow (acrylic fiber precursor) is used to produce high tenacity carbon fiber.

Modacrylic fibers have low softening temperatures that allow them to be stretched, embossed and molded into special shapes. The fibers may be produced with controlled heat shrinkage .capacities