Increasing domestic requirements and tendency to have special textiles are the most reasons for expanding microfibers technology. Microfibers are about half of the silk fiber diameter, one third of cotton fibers, a quarter of the wool fibers and thousand times thinner than human hair.

Fabrics made using microfibers are lighter, more durable, more flexible, more breathable and resistant to pilling.

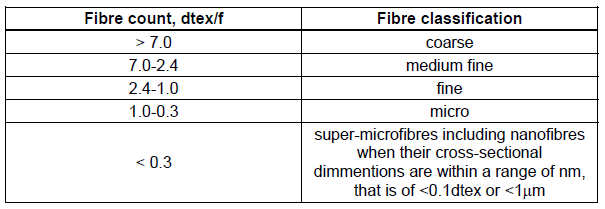

Microfiber refers to those filament and staple fibers with 0.3-1 dtex linear density. Moreover, super-microfibers (fiber count less than 0.3 dtex) can be produced.

The following table shows the relationship between fiber count and fiber classification.

Although the microfiber production technology is old, its domestic usage development dates back to 1980s. Toray, Teijin, Hoechst, DuPont, ICI are most famous companies in microfibers production. Toray has manufactured polyester microfibers with 0.05 linear density. This is one of the finest fiber has been produced.

Raw material quality, purity and molecular weight distribution of the polymer, is very important to have a high quality product.

On the hand, each step of the process is essential for the final quality for example the drying step should be uniform or the granule humidity should be lower than 0.005% to reduce the hydrolytic degradation of the polymer in the melt spinning step. To increase the granule quality, it had better to have continuously dry them.