This paper is related to textile industry especially to Yarn manufacturing process. Defects rate of product plays a very important role for the improvement of yield and financial conditions of any company. Actually defects rate causes a direct effect on the profit margin of the product and decrease the quality cost during the manufacturing of product. Companies strive to decrease the defects rate of the product during the manufacturing process as much as possible. By checking and inspection of defects of product at different point in a production cycle and management implement some changes specifically at those points in production where more defects are likely to happen. The paper of defects rate of textile product in the yarn manufacturing process is so important in industry point of view. This process has large departments where the cotton passes in different process and may be effects the quality of yarn when it reaches the package form. Final package of yarn is the end product and from it is direct send to the customers and if any final product passes with some defects and may chance the customer complaint. The main thing of this paper is to give the understanding of different problems in different parts of yarns in quality point of view. Now days, defects rate reduction is so important especially in recession days, when every company wants to improve the financial goals and reduce quality cost of product.

Yarn Faults in Textile Spinning:

Yarn plays an important role in textile spinning. Defect free yarns make the successive process very smooth and easy. If there are defects in yarn and it cannot be identified before weaving or knitting or yarn dyeing process, then it will be very costly damage for the manufacturer. As its importance, yarn should be checked or inspected not only during spinning but also in weaving, knitting or yarn dyeing processes. There are different types of yarn faults arise in textile industry. This article is presented some common defects of yarn with their explanations.

Types of Yarn Faults and Package Defects in Spinning:

Common yarn faults and package defects are listed in the below:

- Slubs

- Cracker

- Spinners doubles

- Slough off

- Neps including:

L (Loose Fiber Nep)

K (Knot Fiber Nep)

T (Trash Nep)

H (Husk Nep)

- thick and thin places

- Hairy yarn

- Low strength of yarn

- Bad piecing

- Foreign matters

From all the above yarn faults, some important yarn faults have discussed in the following:

- Slubs:

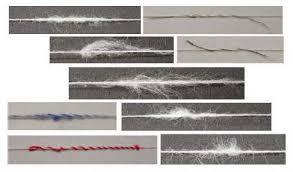

Slubs are fish-shaped thick places from 1-4cm long and about 5-8 times longer than the average yarn diameter at the thickest portion.

- Cracker:

Crackers are short coil like places in the yarn. When the yarn is stretched the coil like fault gets straightened sometimes with a cracking sound, which is the reason for naming this fault as cracker.

- Spinners Doubles:

As the name itself suggests, this type of yarn fault consists of the yarn becoming double in its thickness at some portions. This fault is seen in the fabric as thick yarn in the warp or weft.

4.Slough Off:

Slough off is the result of a package fault by which coils of yarn slip off the package during unwinding of yarn from the bobbin at winding machine.