Spandex, Lycra or Elastin is a type of synthetic fiber that is very popular due to its good elasticity. This fiber is a type of copolymer that was discovered in 1958 by a chemist named Joseph Shivers at DuPont. Regardless of the method used to produce spandex, the chemical structure of the final product will be the same, but the different terms used for this polymer may cause confusion for consumers. , and in countries like England, Ireland, Portugal, Spain, Latin America, Australia and New Zealand, the word Lycra is used. Lycra is a term used commercially by DuPont.

In 2014, researchers found that clothes containing Lycra are not biocompatible and cause many environmental problems. The negative impact of these fibers is more than other synthetic fibers. Other synthetic fibers such as nylon are produced from sources such as oil or coal, but Elastane is completely synthesized in the laboratory. If renewable resources are used for its production, its environmental problems will be reduced.

Spandex fibers can be produced in the following four ways:

- melt extrusion

- reaction spinning

- solution dry spinning

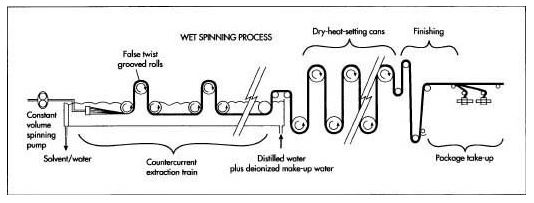

- solution wet spinning

All these methods in the first stage include the interaction between monomers in order to produce polymer. When the polymer is formed, fibers are formed during different processes. Currently, more than 94.5% of spandex fibers in the world are produced by solution dry spinning.

Two types of flexible macro glycol and stiff diisocyanate can be used as raw materials for producing the main chain of this polymer. This macro glycol can be polyester, polyether, polycarnate or a combination of them. The proposed polymers are long chain polymers with hydroxyl groups at both ends, and their most important feature is their length and flexibility. Diisocyanate has a shorter chain and has an isocyanate group at both ends, which makes it hard and leads to chain strength.

The production steps of this polymer are as follows:

Reaction of polymers: In the first step, macro glycol monomers are combined with diisocyanate in specific proportions. The most common ratio for them is 2:1 (glycol: diisocyanate). In the dry spinning stage, the prepared prepolymer is combined with a certain amount of diamine, which is called the chain development stage. Then the resulting mixture is diluted with a suitable solvent to obtain a spinning solution.

Production of fibers: the spinning solution is taken out of the openings of the filament maker, and in the meantime, it is heated in an environment containing nitrogen and gaseous solvent, and in this way, the polymer solution becomes solid. Next, in order to reach the desired thickness, the strands are placed together using an air compressor.

Final process: Finally, the fibers are processed using additional materials. Polydimethylsiloxane and magnesium stearate can be mentioned among these compounds. These materials prevent the fibers from sticking together and facilitate the subsequent processes.