Nowadays, smart textiles especially wearable smart textiles have been paid great attention and in 2 recent years, the existence of Covid 19 forced a lot of scientists to improve them quickly.

The combination of sensors with wearable smart textiles is one of the most interesting fields for scientists. Smart watches which control the heart rate function and send the results to the person’s smart phone to analyze them, is one of the common examples.

The major goal of using smart textile in particular wearable sensors is to long-term monitoring one of the human organ function without any time and place limitation. Use of wearable sensors enables the evaluation of body performance of athletes and patients in a careful and safe way.

So the main challenge for these textiles is how to incorporate the following two features together. The product must have had both cloths’ and sensor features.

Electrical smart textile (e-textile) are fabrics with ability to interact with external environment. Health and medical is one of the leadings in the development of smart textile, so that the 2015 – 2025 year is called e – Textile and the market volume of these textiles has forecasted to hit $ 5.55 billion in the next five years. These textiles owe their development speed to technologies that allow miniaturizing the components.

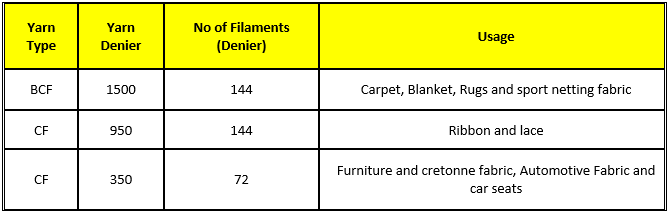

Choosing yarn to produce e – Textile is one of the fundamental parameters as it is highly effective on both production yield and the product properties such as the end operation of sensor, elasticity, comfort, and lifetime.

in order to produce smart textiles, depending on application, different fibers such as cellulose, viscose, polyamide, polyester and etc can be used.

The battery lifetime, the durability of the supply during the monitoring period, the interface of the skin and the sensor, the mechanical changes of the sensor which leads to a reduction in the capacity of the sensor, and reduce the noise in order to accurately measurements are the key factors in sensor smart textile design.

Techniques for Construction of Electrical textiles:

There are two methods to produce electro-conductive textile.

- Wire design

- Coating

The design of the wire is actually a mechanical process whereby using the machinery of converts the raw material into thin threads. After this step, the prepared microfilaments are kept at a high temperature of about 600 to 900 ºC to regain their mechanical and electrical properties. The wires are then cooled and collected on bobbins. The major materials used in this method are copper, silver, bronze, steel, etc. The fibers obtained with this method are resistant to washing and sweating and are also harmless. But their production methods are not simple and need specific machines.

The second method involves surface coating of filaments without electrical conductivity with conductive polymers or metals. This surface could be fibers, yarns and fabrics. This coating can be done by different methods such as chemical polymerization, electrochemical precipitation, dip-coating and sputtering. Two methods of sputtering and chemical polymerization are PVD method. During this process, a thin layer of desired material is deposited onto the surface of the matrix. In the electrochemical deposit method, the desired matrix is immersed in a solution of the intended metal ions and coated on the surface with an electric current.

In the dip-coating method, the matrix is immersed in a conductive solution, and then at high temperature the solvent is evaporated and fixation is performed.

Iran Yarn website is the best link between Iran and other countries in the field of yarn, fibers and other textilesIf you want to import from or export to Iran, please contact us.